The Difference between Absolute, Gauge and Differential Pressure Modes

Quick Summary: Reservoir analysis and gas measurement algorithms require absolute pressure as inputs. All Calscan recorders (Hawks, Badgers, Falcons, etc...) record in absolute when measuring static pressure. When gauge pressure is displayed, they use a fixed offset to account for atmospheric pressure, and do not account for the changing pressure conditions of atmospheric pressure, as this is not needed. If a differential pressure is required, a special sensor needs to be used in order to ensure full accuracy.

One of the key ways to measure the performance of any oil or gas well is to measure its pressure. To avoid ambiguity when referring to a pressure value it is important to specify its mode. There are three commonly used modes: absolute, gauge, and differential pressure. Measuring with an improper mode will lead to an increase in measurement error so it is important for the operator and engineer analyzing the data to fully understand the different modes, which mode they should be using for a particular test, and which ones are available on Calscan measurement tools.

What are pressure modes?

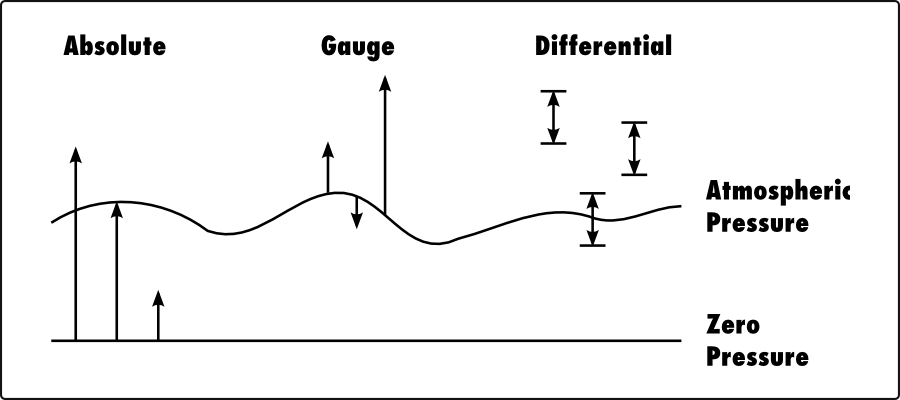

Measuring pressure can only be done when you compare it against another known pressure. This pressure is called the reference pressure. Depending on what the reference pressure is gives us the three modes: absolute, gauge, and differential.

If a vessel were to be completely empty, containing no molecules whatsoever the pressure would be zero. When you are using this zero as the pressure reference point, the measurement mode is called absolute pressure because there is no lower pressure than the absence of all molecules. An example of something that is close to absolute zero pressure would be outer space, but even there, there are some molecules. It is important to note that it is impossible to go below zero when measuring in absolute pressure, so the the concept of a negative absolute pressure is meaningless.

There are many applications where measuring pressure is not really dependent on the absolute pressure, but instead the difference between it and the pressure of the atmosphere. When using the atmospheric pressure as the reference point we call this mode gauge pressure. The classic example is a tire: on a typical tire the pressure is desired to be 30 psi ( 207 kPa ) above atmospheric pressure. A gauge pressure of zero would mean a flat tire, even though there is technically still atmospheric air pressure in it (ie: a non-zero absolute pressure value). The difference between the absolute pressure and gauge pressure value is the variable value of atmospheric pressure:

Absolute pressure = gauge pressure + atmospheric pressure

In some cases, for example when measuring the pressure on the inlet of a compressor, it is the value of the pressure reduction below the external 'reference' atmospheric pressure which is required, rather than the absolute value of the pressure.

In other applications, where knowledge of the pressure difference between two places or systems is needed, the reference pressure may not necessarily be either zero or atmospheric pressure but some other value. These are known as differential pressures. For example, the flow of gas along a pipeline depends on the pressure difference between the ends of the pipe and in practice both ends are usually at comparatively high pressures. Another example common in the oil field is gas flow measurement using an orifice plate. It is an important parameter in the gas flow measurement algorithms to know the differential pressure across the plate to properly calculate the gas flow.

Which pressure modes should I use?

If serious errors are to be avoided, it is important when making pressure measurements to be clear which mode of measurement is being employed: absolute, gauge (positive or negative) or differential. The three pressure modes are illustrated below, note the changeable reference line for gauge pressure that illustrates the changeable nature of atmospheric pressure.

When measuring the static pressure on an oil or gas well, all calculations for reservoir analysis are done in absolute pressure. This would include downhole or surface pressure build ups or measuring gas rates. Why? Simply that an oil or gas well does not respond to changes in atmospheric pressure, so using atmospheric pressure as your reference point would only result in errors since atmospheric pressure will vary during the length of the test. Not to mention in the case of a downhole pressure recorder it would be very difficult to measure in gauge, as measuring the pressure 5000 meters down a well and at the same time referencing the pressure to atmosphere would be somewhat challenging. In the case of gas rates all gas calculations used in industry (AGA3, AGA7, AGA8, ISO5167 …) use the static up-stream pressure in absolute.

So you may ask why in the oilfield is it so common to view the pressure in gauge. Before the advent of electronic sensors it was far easier to measure in gauge as all the recorders were mechanical in nature and depended on simple Bourdon tubes to measure pressure. Since the size of these devices made it difficult to put them in a vacuum chamber to be calibrated, manufactures and technicians zeroed the sensors to the next handy reference pressure, the atmosphere. The error induced by referencing to atmospheric pressure was not a large factor in the total error of the tool, as the mechanical sensor was fairly inaccurate +/- 0.5% FS (full-scale). In the 1990’s the advent of precision vacuum referenced pressure sensors changed things, and made using atmospheric pressure as a reference obsolete as accuracies are in the range of +/- 0.05% FS or better. At this level of accuracy an atmospheric pressure reference would significantly reduce the overall accuracy of the sensor due to the constantly varying nature of atmospheric pressure. A day to day change of 1 kPa is not uncommon, and can exceed 2 kPa when a storm front moves through.

Which pressure modes does Calscan equipment use?

When measuring static pressure all Calscan equipment (such as a Hawk, Badger, Falcon, etc..) uses a sensor that has a built in vacuum as its zero reference. At no point do we measure the actual atmospheric pressure, since true gauge pressure is almost never required in the oilfield. On Calscan equipment there is an option to allow viewing in gauge pressure, as most field techs do not understand the different pressure modes and want the sensor to read zero at atmosphere. When viewing in gauge pressure it is in fact a pseudo gauge pressure that subtracts the average atmospheric pressure at the height above sea level the unit was programmed for. So for example in Edmonton, Alberta the height above sea level 668 m (2192 feet) at this level the average atmospheric pressure is 93 kPaa (13.49 psia) this is then subtracted from the absolute pressure measured to give the appearance of a true gauge pressure. The average pressure being subtracted is called the station pressure. It is important to note as atmospheric pressure is constantly changing the sensor might read a few kPa higher or lower than zero if the atmospheric pressure is being measured directly with the sensor.

The actual data being stored is always in absolute pressure. This is so when the data is exported to various engineering programs it can be exported in absolute pressure even though it was viewed in a pseudo gauge pressure in the field. This ensures the most accurate pressure measurement possible.

In the case where a differential pressure is needed, for example when the pressure across an orifice plate is needed for gas flow measurement, a special differential pressure sensor is used to give the most accurate pressure measurement.